An Electrical Service Grounding System Design is the process of planning and implementing a safe, effective grounding and bonding system for an electrical power distribution network. Grounding is one of the most critical aspects of electrical system safety, as it provides a low-impedance path for fault currents, stabilizes system voltage, and protects people, equipment, and property.

An Electrical Service Grounding System Design is the process of planning and implementing a safe, effective grounding and bonding system for an electrical power distribution network. Grounding is one of the most critical aspects of electrical system safety, as it provides a low-impedance path for fault currents, stabilizes system voltage, and protects people, equipment, and property.

Purpose of Grounding System Design

The main objectives of grounding are to:

- Protect People from Electric Shock

- Ensures exposed conductive parts (like enclosures and panels) do not remain energized during faults.

- Provide a Path for Fault Currents

- Safely direct fault current to ground to trip protective devices like breakers or fuses.

- Stabilize Voltage During Transients

- Reduces voltage fluctuations caused by lightning, switching surges, or utility faults.

- Comply with Codes and Standards

- Must meet the requirements of NEC Article 250, IEEE 142 (Green Book), NFPA 70E, and UL standards.

- Prevent Equipment Damage

- Protects transformers, generators, motors, and sensitive electronics by preventing overvoltage conditions.

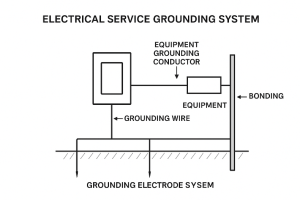

Key Components of a Grounding System

A properly designed electrical service grounding system typically includes the following:

- Grounding Electrode System

The physical connection between the electrical system and the earth.

Common grounding electrodes include:

- Ground rods (driven rods)

- Concrete-encased electrodes (Ufer ground)

- Metal water pipe (if permitted by NEC)

- Ground rings (wire buried around the building perimeter)

- Structural steel embedded in concrete

- System Grounding (Neutral Grounding)

Connecting one point of the electrical system—typically the neutral of a transformer or generator—to ground.

Types of system grounding:

- Solidly grounded – most common in commercial buildings.

- Resistance grounded – used in industrial settings to limit fault current.

- Ungrounded – rarely used, for specialized processes.

- Equipment Grounding Conductors (EGCs)

- Bond metal enclosures, raceways, and non-current-carrying conductive parts to the grounding system.

- Examples:

- Conduit

- Cable armor

- Panelboards

- Motor frames

- Bonding

- Bonding connects all metal parts and grounding components together to eliminate potential differences.

- This is critical for:

- Building steel

- Water piping

- Gas piping

- Communication systems

- Lightning protection systems

- Grounding Busbars

- Central points in electrical rooms where grounding conductors and bonds converge.

- Often used in data centers and large industrial plants.