An Electrical Service Power Harmonic Study is an engineering analysis focused on identifying, measuring, and mitigating harmonic distortion within an electrical power system. Harmonics are unwanted voltage or current waveforms that distort the ideal sinusoidal shape of AC power, leading to equipment stress, inefficiencies, and reliability issues.

An Electrical Service Power Harmonic Study is an engineering analysis focused on identifying, measuring, and mitigating harmonic distortion within an electrical power system. Harmonics are unwanted voltage or current waveforms that distort the ideal sinusoidal shape of AC power, leading to equipment stress, inefficiencies, and reliability issues.

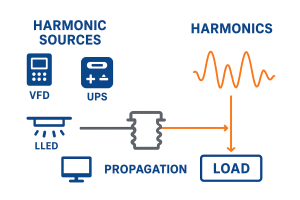

This type of study is especially important in facilities with a high concentration of non-linear loads, such as computers, variable frequency drives (VFDs), LED lighting, or industrial equipment.

Purpose of a Harmonic Study

The main goals of a harmonic study are to:

- Identify Sources of Harmonics

- Locate equipment causing distortion, such as VFDs, UPS systems, or certain electronic devices.

- Assess Harmonic Levels

- Determine how much total harmonic distortion (THD) exists in the system.

- Prevent Equipment Damage

- Protect transformers, cables, circuit breakers, and motors from overheating or premature failure.

- Ensure Compliance

- Verify compliance with standards such as:

- IEEE 519 – Recommended Practices and Requirements for Harmonic Control.

- NEC – Requirements for certain installations.

- Verify compliance with standards such as:

- Design Mitigation Solutions

- Suggest corrective actions, such as filters or system upgrades, to keep harmonics within acceptable limits.

What Are Harmonics?

- Normal power waveform: A smooth, 60 Hz (or 50 Hz) sine wave.

- Harmonics: Additional frequencies at integer multiples of the fundamental frequency (e.g., 120 Hz, 180 Hz, 240 Hz).

- These distortions are generated by non-linear loads, which draw current in abrupt pulses instead of smoothly.

Common sources of harmonics:

- Variable frequency drives (VFDs)

- UPS systems

- LED lighting systems

- Data centers and server farms

- Large numbers of computers or office equipment

- Arc furnaces or welders

Key Components of a Harmonic Study

A harmonic study typically includes the following steps:

- Data Collection

- Review the facility’s one-line diagram.

- Collect equipment information:

- Load types and sizes

- Transformer specifications

- Cable sizes

- Breaker ratings

- Utility data for incoming power

- Harmonic Measurements (Field Testing)

- Use power quality analyzers to measure:

- Voltage and current harmonic levels

- Total Harmonic Distortion (THD)

- Specific harmonic orders (3rd, 5th, 7th, etc.)

- Identify whether the harmonic problem originates inside the facility or from the utility.

- Computer Modeling & Analysis

- Build a digital model of the electrical system using software like:

- ETAP

- SKM PowerTools

- EasyPower

- Simulate harmonic propagation throughout the system.

- Compare with Standards

- Evaluate results against IEEE 519 limits:

- THD limits for voltage and current.

- Identify areas where harmonics exceed allowable thresholds.

- Develop Solutions

If harmonics are excessive, possible mitigation strategies include:

- Passive harmonic filters – tuned to specific harmonic frequencies.

- Active harmonic filters – dynamic systems that neutralize harmonics.

- Phase shifting transformers – reduce harmonic contributions from drives.

- Drive replacement or upgrade – use 12-pulse or 18-pulse VFDs.

- System reconfiguration – redistribute loads to balance harmonics.

Deliverables in a Harmonic Study

A professional harmonic study report usually includes:

- Updated one-line diagram.

- Graphs of measured harmonic levels.

- THD percentage and breakdown by harmonic order.

- Comparison to IEEE 519 compliance thresholds.

- Recommended corrective actions.

- Cost-benefit analysis for mitigation solutions.

Why Harmonic Studies Are Important

Harmonics can lead to serious problems if ignored, including:

- Overheating of transformers, cables, and motors.

- Nuisance tripping of circuit breakers and protective devices.

- Reduced efficiency, leading to higher energy bills.

- Failure of sensitive electronics due to voltage distortion.

- Utility penalties for poor power quality.

Industries That Commonly Require Harmonic Studies

- Manufacturing plants with VFDs and robotics.

- Hospitals with sensitive imaging equipment.

- Data centers with high concentrations of servers and UPS systems.

- Commercial buildings with extensive LED lighting.

- Industrial facilities with welding or arc furnaces.

Contact us to see if a harmonic study is needed for your company.