Vacuum Degassing of Transformer Oil

Vacuum Degassing of Transformer Oil

Vacuum degassing is a key process in removing dissolved gases and moisture from transformer oil, essential for maintaining its dielectric strength and insulating performance.

Transformer oil can absorb:

-

Moisture (H₂O vapor)

-

Dissolved gases (oxygen, nitrogen, CO₂, hydrogen, etc.)

These impurities reduce the oil’s breakdown voltage (BDV) and can cause internal arcing or insulation failure.

Vacuum degassing uses low pressure (vacuum) to extract these contaminants from the oil.

Why It’s Important

| Without Degassing | With Degassing |

|---|---|

| Low BDV (<30 kV) | High BDV (>60 kV) |

| Promotes oxidation | Prolongs oil life |

| Accelerates aging | Protects windings |

| Increases failure risk | Reduces faults |

How the Process Works

-

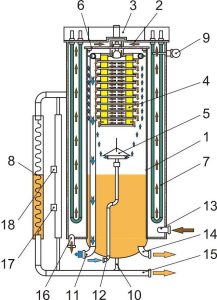

Oil Preheating

-

Oil is heated to ~60–70°C to reduce viscosity and improve degassing efficiency.

-

-

Vacuum Chamber

-

Oil enters a vacuum chamber, where pressure is dropped (0.3 to 1 mbar).

-

Lower pressure = lower boiling point = moisture & gases vaporize.

-

-

Spray Nozzles or Spreaders

-

Oil is sprayed into thin films to maximize surface area for degassing.

-

-

Vapors Removed

-

Extracted gases and water vapor are pulled by a vacuum pump and condensed or vented safely.

-

-

Filtered & Cooled Oil

-

Degassed oil is passed through filters (to remove particles) and coolers before returning to the transformer.

-

Inline or Offline Use

| Mode | Used For |

|---|---|

| Inline (energized transformer) | Live oil filtration with mobile units |

| Offline (de-energized) | Oil drained and treated separately or processed through transformer |

Typical Results After Vacuum Degassing

| Parameter | Before | After |

|---|---|---|

| Moisture (ppm) | 50–100 | <10 ppm |

| Gas content (%) | 8–10% | <1% |

| BDV (kV) | 20–30 | >60 |

Standards & Guidelines

-

IEC 60422 – Maintenance of insulating oils

-

ASTM D1816 / D877 – BDV testing

-

IEEE C57.106 – Oil maintenance guidelines

Best Practices

-

Test oil before and after degassing (BDV, moisture, gas content)

-

Use dry nitrogen blanket after treatment (to avoid reabsorption of air)

-

Perform degassing as part of oil reconditioning or during commissioning of new transformers